Qhov loj me me ntawm cov xuab zeb nyoos muaj feem cuam tshuam rau qhov zoo ntawm castings.Thaum siv coarser grit, molten hlau nyiam nkag mus rau hauv cov tub ntxhais grit, uas ua rau lub ntsej muag tsis zoo.Kev siv cov xuab zeb zoo dua tuaj yeem tsim qhov zoo dua thiab ua kom zoo dua qub, tab sis yuav tsum muaj cov ntaub ntawv ntau dua, thiab tib lub sijhawm txo cov huab cua permeability ntawm cov tub ntxhais, uas yuav ua rau muaj qhov tsis xws luag.Nyob rau hauv cov txheej txheem xuab zeb casting, tshwj xeeb tshaj yog thaum siv silica xuab zeb, cov xuab zeb nyoos feem ntau nyob rau hauv cov nram qab no:

Qhov nruab nrab fineness 50-60 AFS (nruab nrab particle loj 220-250 μm): zoo deg zoo thiab qis binder pab

Cov hmoov zoo (tsawg dua 200 mesh) cov ntsiab lus ≤2%: tuaj yeem txo cov binder

Cov ntsiab lus av nkos (particle cov ntsiab lus tsawg dua 0.02mm) ≤0.5%: tuaj yeem txo cov binder

Particle loj faib: 95% ntawm cov xuab zeb yog concentrated nyob rau hauv 4th los yog 5th sieve: yooj yim rau compact thiab txo o tsis xws luag

Huab cua permeability ntawm cov xuab zeb qhuav: 100-150: txo qhov pore tsis xws luag

Ceramic xuab zeb, vim nws yuav luag puag ncig particle zoo, zoo heev fluidity, siab huab cua permeability, thiab cov yam ntxwv ntawm dav particle loj tis thiab ib leeg-mesh ua ke nyob rau hauv cov txheej txheem ntau lawm, nyob rau hauv casting xyaum, ntxiv rau ua raws li cov saum toj no cov yam ntxwv, muaj nws tus kheej tshwj xeeb gradation yam ntxwv ua rau nws tsis muaj kev sib cais thiab delamination thaum lub sij hawm kev thauj mus los thiab kev thauj mus los;nws muaj zog ntub dej zoo nyob rau hauv daim ntawv thov ntawm ntsuab pwm xuab zeb thiab tsis-ci resin xuab zeb.Rau cov txheej txheem xuab zeb casting siv cov binders, kev siv cov khoom siv sib faib ua rau cov khoom me me sau rau hauv qhov sib txawv ntawm cov khoom loj thiab sib xyaw ua ke, ua rau "txuas txuas" ntawm cov ntawv khi, yog li txhim kho cov khoom sib txuas ntawm cov tub ntxhais, thiab lwm yam. . Nws yog ib txoj hauv kev zoo.

Summary daim ntawv thov ntawm ceramic xuab zeb rau ntau tshaj 20 xyoo, particle loj yuav tsum tau thiab kev faib ntawm ceramic xuab zeb siv nyob rau hauv txawv casting txheej txheem yog roughly teev raws li nram no:

● RCS (Resin Coated Ceramic Sand)

AFS qhov tseem ceeb ntawm 50-70, 70-90, thiab 90-110 yog tag nrho siv, faib hauv 4 lossis 5 sieves, thiab cov concentration siab dua 85%;

● Tsis muaj ci hauv cov xuab zeb

(xws li furan, alkali phenolic, PEP, Bonnie, thiab lwm yam): AFS 30-65 yog siv, 4 sieves los yog 5 sieves tis, qhov concentration yog tshaj 80%;

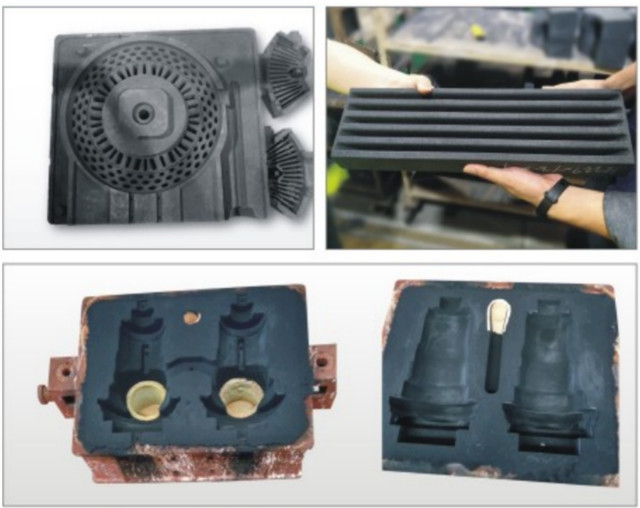

● Poob Ua Npuas Ncauj Txheej Txheem / Poob Nyhav Foundry Txheej Txheem

10/20 mesh thiab 20/30 mesh yog siv ntau dua, uas tuaj yeem txhim kho huab cua permeability, xyuas kom cov nqi rov ua dua ntawm cov xuab zeb ceramic tom qab nchuav, thiab txo kev noj;

● Txias Box Sand Txheej Txheem

AFS 40-60 feem ntau siv, faib nrog 4 lossis 5 sieves, thiab cov concentration siab dua 85%;

● 3D Sand Printing

2 sieves yog faib, mus txog 3 sieves, nrog ib tug concentration ntawm ntau tshaj 90%, kom ntseeg tau ib tug uniform xuab zeb txheej thickness.Qhov nruab nrab fineness yog dav faib raws li kev siv sib txawv

Post lub sij hawm: Mar-27-2023