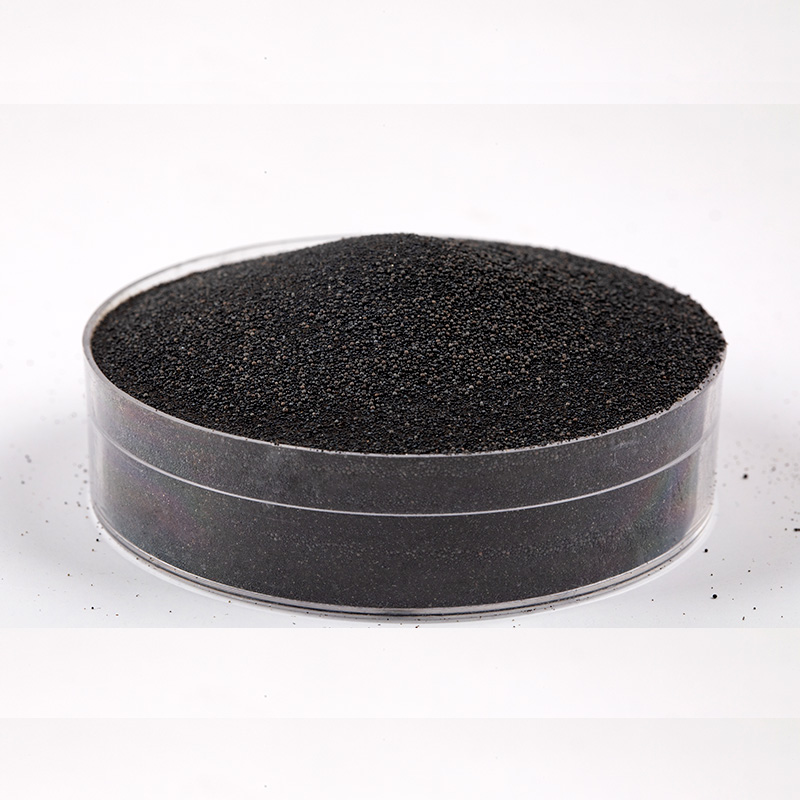

Ceramic Foundry Sand

Features

• Uniform component composition

• Stable grain size distribution and air permeability

• High refractoriness (1825°C)

• High resistance to wear, crush and thermal shock

• Little thermal expansion

• Excellent fluidity and filling efficiency owing to being spherical

• Highest reclamation rate in the sand loop system

Application Sand Foundry Processes

Resin coated sand process

Cold box and warm box sand process

3D sand printing process

No-bake resin sand process (Include Furan resin and Alkali phenolic resin)

Investment process/ Lost wax foundry process/ Precision casting

Lost weight process/ Lost foam process

Water glass process

Ceramic Sand Property

| Main Chemical Component | Al₂O₃ 70-75%,

Fe₂O₃<4%, |

| Grain Shape | Spherical |

| Angular Coefficient | ≤1.1 |

| Partical Size | 45μm -2000μm |

| Refractoriness | ≥1800℃ |

| Bulk Density | 1.8-2.1 g/cm3 |

| PH | 6.5-7.5 |

| Application | Steel, Stainless steel, Iron |

Grain Size Distribution

|

Mesh |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | AFS Range |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | |

| #400 | ≤5 | 15-35 | 35-65 | 10-25 | ≤8 | ≤2 | 40±5 | ||||

| #500 | ≤5 | 0-15 | 25-40 | 25-45 | 10-20 | ≤10 | ≤5 | 50±5 | |||

| #550 | ≤10 | 20-40 | 25-45 | 15-35 | ≤10 | ≤5 | 55±5 | ||||

| #650 | ≤10 | 10-30 | 30-50 | 15-35 | 0-20 | ≤5 | ≤2 | 65±5 | |||

| #750 | ≤10 | 5-30 | 25-50 | 20-40 | ≤10 | ≤5 | ≤2 | 75±5 | |||

| #850 | ≤5 | 10-30 | 25-50 | 10-25 | ≤20 | ≤5 | ≤2 | 85±5 | |||

| #950 | ≤2 | 10-25 | 10-25 | 35-60 | 10-25 | ≤10 | ≤2 | 95±5 |

Write your message here and send it to us