1. What is ceramic sand?

ceramic sand is mainly made of minerals containing Al2O3 and SiO2 and added with other mineral materials. A spherical foundry sand made by powder, pelletizing, sintering and grading processes. Its main crystal structure is Mullite and Corundum, with rounded grain shape, high refractoriness, good thermochemical stability, low thermal expansion, impact and abrasion resistance,features of strong fragmentation. Ceramic sand can be used to produce high quality castings by any kinds of sand casting processes.

2. Application area of ceramic sand

Ceramic sand has been popularly used in foundries of most kinds of foundry technologies, such as resin coated sand, self-harden process (F NB, APNB and Pep-set), cold box, hot box, 3D printing sand, and lost foam process.

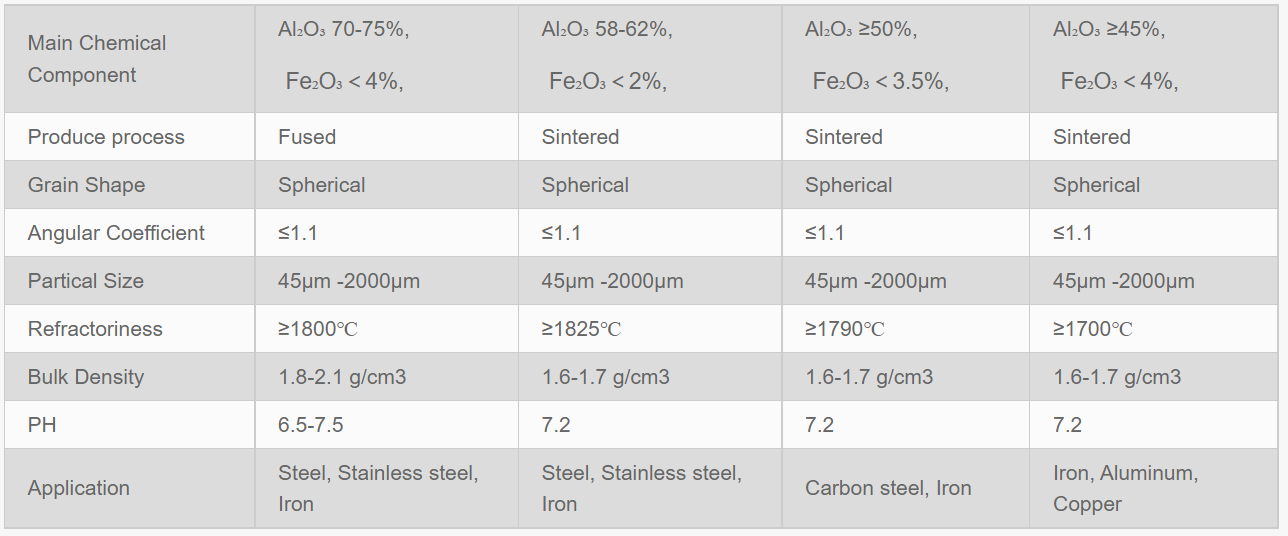

3. The specification of ceramic sand

SND can provide ceramic sand of various specifications. For chemical composition, there are high aluminum-oxide, medium aluminum-oxide sands and lower aluminum-oxide sands, which use against different castings material. All have a widely ranged particle size distribution to satisfy customer’s demands.

4. The properties of ceramic sand

5. Particle size distribution

|

Mesh |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | AFS Range |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | |

| #400 | ≤5 | 15-35 | 35-65 | 10-25 | ≤8 | ≤2 | 40±5 | ||||

| #500 | ≤5 | 0-15 | 25-40 | 25-45 | 10-20 | ≤10 | ≤5 | 50±5 | |||

| #550 | ≤10 | 20-40 | 25-45 | 15-35 | ≤10 | ≤5 | 55±5 | ||||

| #650 | ≤10 | 10-30 | 30-50 | 15-35 | 0-20 | ≤5 | ≤2 | 65±5 | |||

| #750 | ≤10 | 5-30 | 25-50 | 20-40 | ≤10 | ≤5 | ≤2 | 75±5 | |||

| #850 | ≤5 | 10-30 | 25-50 | 10-25 | ≤20 | ≤5 | ≤2 | 85±5 | |||

| #950 | ≤2 | 10-25 | 10-25 | 35-60 | 10-25 | ≤10 | ≤2 | 95±5 |

6. The kinds of foundry sands

There are two kinds of foundry sand popularly used, natural and artificial.

The commonly used foundry sands are silica sand, chromite sand, olivine, zircon,ceramic sand and cerabeads. The ceramic sand and cerabeads are artificial sand, others are nature sand.

7. The refractoriness of popularly foundry sand

Silica sand: 1713℃

Ceramic sand: ≥1800℃

Chromite sand: 1900℃

Olivine sand: 1700-1800℃

Zircon sand: 2430℃

Post time: Mar-27-2023